Product Introduction

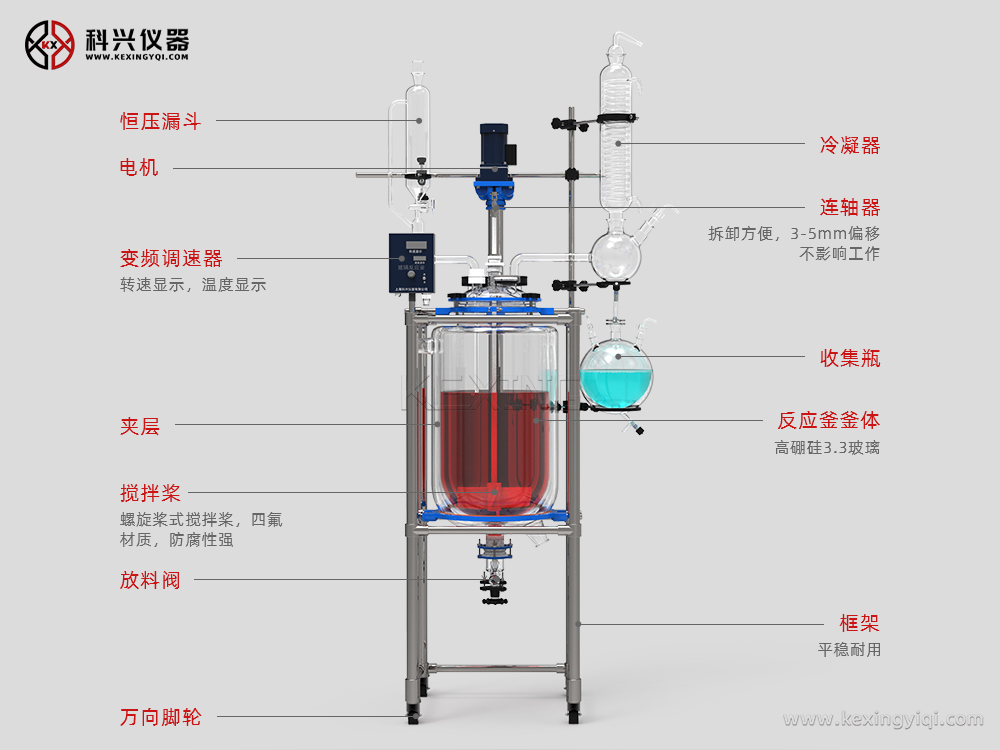

The double-layer glass reaction vessel is designed with double-layer glass. The inner layer is filled with reaction solvent for stirring reaction, and the interlayer can be connected to different cold and heat sources (freezing liquid, hot water or hot oil) for high-temperature reaction (equipped with corresponding circulating oil bath, temperature can reach 300 ℃) or low-temperature reaction (equipped with corresponding low-temperature freezing liquid circulation system, temperature can reach -80 ℃). Alternatively, a heating and cooling integrated circulation machine can be selected; Under constant temperature conditions, the stirring reaction can be carried out in a closed glass reactor under normal pressure or negative pressure according to usage requirements, and the reaction solution can be refluxed and distilled. During use, it can be evacuated to achieve vacuum reaction. It is an ideal pilot and production equipment for modern fine chemicals, biopharmaceuticals, and new material synthesis. Its design makes the experiment safer and more convenient.

Product Display

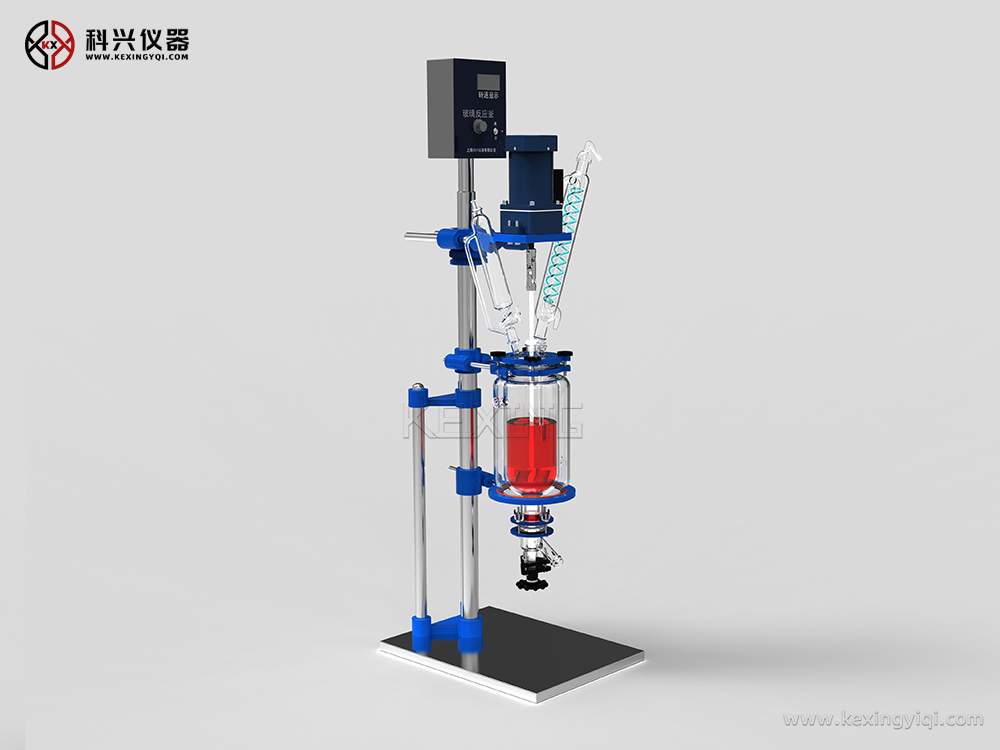

1-10L Jacketed Pilot Plant Reactors

10~20L Jacketed Pilot Plant Reactors

30~100L Jacketed Pilot Plant Reactors

Technical Parameter

| model | RAT-1L | RAT-2L | RAT-3L | RAT-5L | RAT-10L | RAT-20L | RAT-30L | RAT-50L | RAT-100L |

| capacity | 1L | 2L | 3L | 5L | 10L | 20L | 30L | 50L | 100L |

| Reaction bottle (L) | 1 | 2 | 3 | 5 | 10 | 20 | 30 | 50 | 100 |

| Number of bottle openings | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 |

| Diameter of kettle lid (mm) | 150 | 150 | 150 | 180 | 265 | 265 | 265 | 265 | 340 |

| Outer diameter of inner cylinder (mm) | 113 | 135 | 150 | 180 | 230 | 290 | 330 | 365 | 460 |

| Outer diameter of outer cylinder (mm) | 150 | 180 | 200 | 230 | 290 | 330 | 365 | 410 | 500 |

| Height of kettle body (mm) | 250 | 280 | 300 | 400 | 450 | 550 | 730 | 850 | 950 |

| Rotational speed (rpm) | 0-1350 | 0-1350 | 0-1350 | 0-1350 | 0-450 | 0-450 | 0-450 | 0-450 | 0-450 |

| Mixing shaft diameter (mm) | 14 | 14 | 14 | 14 | 14 | 17 | 17 | 17 | 18 |

| Mixing power (w) | 120W electronic speed regulation | 120W electronic speed regulation | 120W electronic speed regulation | 120W electronic speed regulation | 120W reduction motor | 120W reduction motor | 120W reduction motor | 120W reduction motor | 200W reduction motor |

| Voltage/Frequency | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| electronic speed control | ● | ||||||||

| Frequency Control | ○ | ● | |||||||

| Constant pressure funnel | ● | ||||||||

| vertical condenser | ● | ||||||||

| Digital display speed | ● | ||||||||

| temperature sensor | ○ | ● | |||||||

| Temperature measuring tube | ● | ||||||||

| PTFE component sealing | ● | ||||||||

| Sealing of PTFE mechanical components | ○ | ||||||||

| Feeding piston | ● | ||||||||

| Distillation device | ○ | ||||||||

| Reflux device | ● | ||||||||

| Low speed boosting | ○ | ● | |||||||

| Lower the material | ● | ||||||||

| vacuum meter | ○ | ||||||||

| Connector connection | ○ | ||||||||

| Universal joint connection | ● | ||||||||

| Spear type mixing slurry | ● | ||||||||

| Digital temperature display | ○ | ||||||||

| Explosion-Proof Motor | ○ | ||||||||

| Explosion proof controller | ○ | ||||||||

| Explanation: ●Standard configuration; ○ Optional | |||||||||

Your current location:

Your current location: