Product Introduction

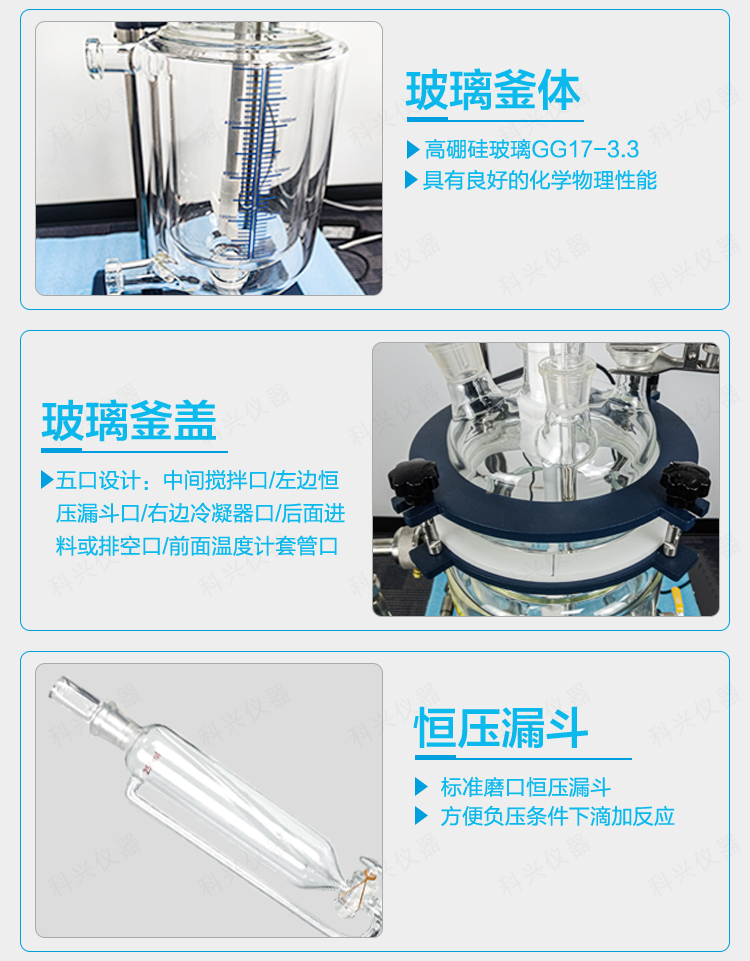

The double-layer glass reactor features a double-layer glass design. The inner layer can hold reaction solvents for stirring reactions, while the interlayer can be connected to different hot or cold sources (refrigerated liquid, hot water, or thermal oil) to perform high-temperature reactions (with a corresponding circulating oil bath, temperatures can reach 300°C) or low-temperature reactions (with a corresponding low-temperature refrigerated liquid circulation system, temperatures can reach -80°C). Alternatively, a combined heating and cooling circulation unit can be selected. Under set constant-temperature conditions, stirring reactions can be carried out in the sealed glass reactor at normal or negative pressure as required. It also allows for reflux and distillation of reaction solutions and can be vacuum-sealed for vacuum reactions. This makes it an ideal pilot or production equipment for modern fine chemical engineering, biopharmaceuticals, and new material synthesis. Its design ensures safer and more convenient experimentation.

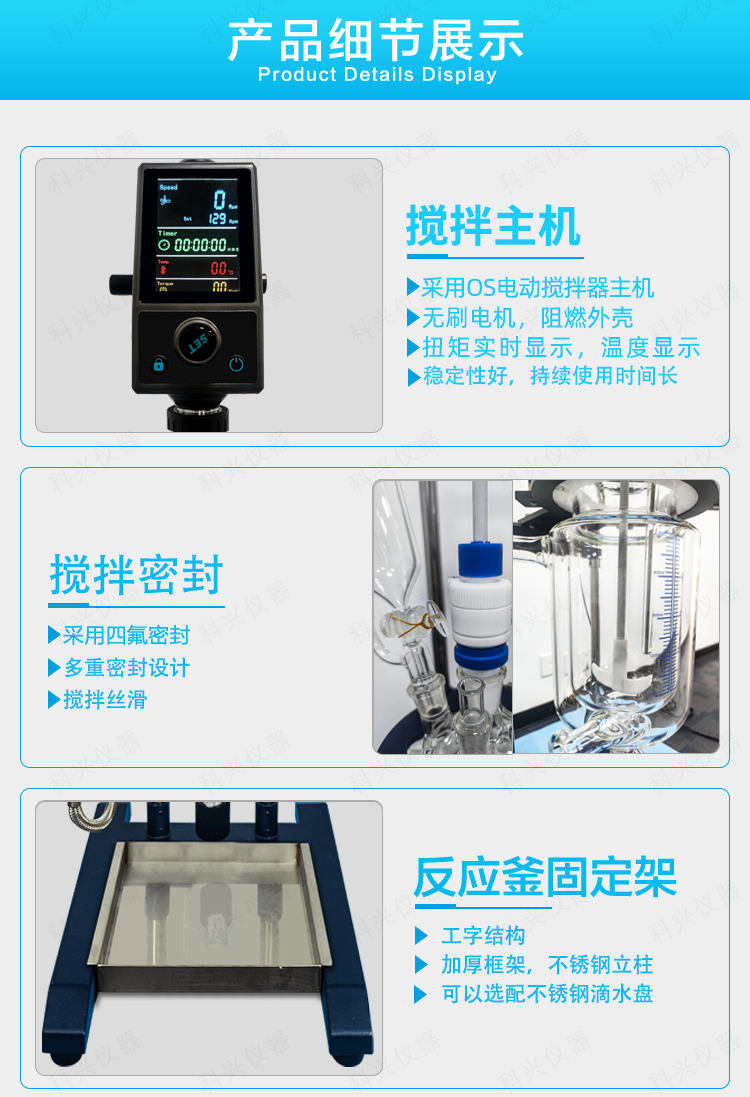

Additionally, the company has developed an upgraded version of 1-5L small glass reactors based on specific customer usage environments. These reactors adopt our OS-Pro series stirrer main unit as the core component, featuring an integrated large screen that displays real-time speed, timing, temperature, and motor torque.

Product Display

Technical Parameter

| 型号 | GRT-1L | GRT-2L | GRT-3L | GRT-5L | |

| 釜体 | 材质 | 3.3硼硅玻璃 | 3.3硼硅玻璃 | 3.3硼硅玻璃 | 3.3硼硅玻璃 |

| 釜内有效容积(L) | 1 | 2 | 3 | 5 | |

| 最小搅拌容量(L) | 约0.13 | 约0.2 | 约0.3 | 约0.5 | |

| 釜口(mm) | 外φ150/内φ100 | 外φ150/内φ100 | 外φ203/内φ170 | 外φ203/内φ170 | |

| 底阀内径(mm) | φ20 | φ20 | φ20 | φ20 | |

| 夹套接口 | 玻璃法兰口35mm(配不锈钢转接头1/2螺纹) | 玻璃法兰口35mm(配不锈钢转接头1/2螺纹) | 玻璃法兰口35mm(配不锈钢转接头1/2螺纹) | 玻璃法兰口35mm(配不锈钢转接头1/2螺纹) | |

| 夹套容积(L) | 1.2L | 1.3L | 2.4L | 3L | |

| 使用温度范围(℃) | -80 ~ 200 | -80 ~ 200 | -80 ~ 200 | -80 ~ 200 | |

| 釜内允许压力 | 负压~常压 | 负压~常压 | 负压~常压 | 负压~常压 | |

| 夹套允许压力(MPa) | 循环状态下≤0.1 | 循环状态下≤0.1 | 循环状态下≤0.1 | 循环状态下≤0.1 | |

| 承受热冲击温度(℃) | <40 | 40 | 40 | 40 | |

| 放料阀出料口外径(mm) | 15mm | 15mm | 15mm | 15mm | |

| 釜盖 | 材质 | 3.3硼硅玻璃 | 3.3硼硅玻璃 | 3.3硼硅玻璃 | 3.3硼硅玻璃 |

| 开口(个) | 5 | 5 | 5 | 5 | |

| 中间搅拌口(标准磨口) | 24 | 24 | 40 | 40 | |

| 侧开口(标准磨口) | 24×3 | 24×3 | 24×2,29×2 | 24×2,29×2 | |

| 19×1 | 19×1 | 35#球磨口×1 | 35#球磨口×1 | ||

| 密封垫 | φ148×φ105×3 | φ148×φ105×3 | φ203×φ170×3 | φ203×φ170×3 | |

| 恒压滴液漏斗 | 容积(ml) | 250 | 250 | 500 | 500 |

| 接口规格 | 24/24 | 24/24 | 29/29 | 29/29 | |

| 冷凝管 | 长度(mm) | 350 | 350 | 430 | 430 |

| 冷凝面积(㎡) | 0.01 | 0.01 | 0.1 | 0.1 | |

| 接口规格 | 24/24 | 24/24 | 29/29 | 29/29 | |

| 回流头 | 接口规格 | 无 | 无 | 球磨口35#/29 | 球磨口35#/29 |

| 搅拌 | 电机类型 | 直流无刷电机 | 直流无刷电机 | 直流无刷电机 | 直流无刷电机 |

| 转速调节范围(rpm) | 50-2200 | 50-2200 | 50-2200 | 50-2200 | |

| 显示方式 | 彩色大屏直显 | 彩色大屏直显 | 彩色大屏直显 | 彩色大屏直显 | |

| 转速显示精度 | ±1rpm | ±1rpm | ±1rpm | ±1rpm | |

| 电机功率(W) | 50 | 50 | 100 | 100 | |

| 搅拌定时范围 | 0-99h59min | 0-99h59min | 0-99h59min | 0-99h59min | |

| 额定扭矩(N.cm) | 22 | 22 | 44 | 44 | |

| 搅拌支撑件材质 | PTFE+PEEK+玻璃 | PTFE+PEEK+玻璃 | PTFE+PEEK+玻璃 | PTFE+PEEK+玻璃 | |

| 搅拌支撑件结构 | 真空机械密封 | 真空机械密封 | 真空机械密封 | 真空机械密封 | |

| 搅拌桨形式 | 锚式(φ10mm-100mm) | 锚式(φ10mm-100mm) | 锚式(φ14mm-120mm)或浆式可选 | 锚式(φ14mm-120mm)或浆式可选 | |

| 搅拌桨材质 | 06Cr19Ni10+PTFE | 06Cr19Ni10+PTFE | 06Cr19Ni10+PTFE | 06Cr19Ni10+PTFE | |

| 温度传感器 | 传感器型号 | PT100 | PT100 | PT100 | PT100 |

| 显示方式 | 数字显示 | 数字显示 | 数字显示 | 数字显示 | |

| 显示精度 | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | |

| 机架材质 | 06Cr19Ni10+碳素结构钢喷塑+铝合金喷塑 | 06Cr19Ni10+碳素结构钢喷塑+铝合金喷塑 | 06Cr19Ni10+碳素结构钢喷塑+铝合金喷塑 | 06Cr19Ni10+碳素结构钢喷塑+铝合金喷塑 | |

| 釜体进出液循环软管接口规格 | RC1/2螺纹 | RC1/2螺纹 | RC1/2螺纹 | RC1/2螺纹 | |

| 放料口高度(mm) | ≤260 | ≤260 | ≤220 | ≤220 | |

| 接收瓶容积(ml) | 选配 | 选配 | 选配 | 选配 | |

| 接液盘 | 选配 | 选配 | 选配 | 选配 | |

| 工作环境温度范围(℃) | 5~35 | 5~35 | 5~35 | 5~35 | |

| 工作环境湿度范围(℃) | ≤70 | ≤70 | ≤70 | ≤70 | |

| 电源 | 100-240V~,50/60Hz | 100-240V~,50/60Hz | 100-240V~,50/60Hz | 100-240V~,50/60Hz | |

| 外形尺寸(宽×深×高)(mm) | 380×500×1110 | 380×500×1150 | 480×540×1320 | 480×540×1380 | |

| 整机重量(kg) | 约19 | 约20 | 约30 | 约32 | |

Your current location:

Your current location: